WOTAN HORIZONTAL BORING AND MILLING MACHINE

CUTMAX 3 FT-K FLOOR TYPE

WITH 4 AXIS SIEMENS 840 D CNC

WOTAN(沃唐) 卧式镗铣床

型号:CUTMAX3FT-

K 落地式

配备西门子840D 4轴数控系统

TECHNICAL SPECIFICATIONS

技术规格

Boring Spindle:

镗杆

|

Spindle diameter 镗杆直径 |

mm |

|

160 |

|

Tool holder 刀柄型号 |

DIN |

|

69871 A50 |

|

Draw stud 拉钉型号 |

DIN |

|

69872 28 |

|

Boring spindle taper 镗杆内孔锥度 |

ISO |

|

50 |

|

Milling spindle tool mount 铣轴刀具安装锥度 |

ISO |

|

65 |

|

Spindle speed range inf. Variable 主轴转速范围,无级变速 |

rpm |

|

2-2000 |

|

|

|

|

|

|

Travels 行程 |

|

|

|

|

|

|

|

|

|

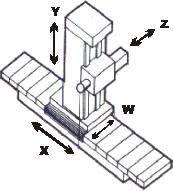

Column cross travel (X) X轴,立柱横向行程 |

mm |

|

6000 |

|

Headstock vertical travel (Y) Y轴,主轴箱垂直行程 |

mm |

|

3000 |

|

Spindle longitudinal travel (Z) Z轴,镗杆纵向行程 |

mm |

|

1000 |

|

Column longitudinal travel (W) W轴,立柱纵向行程 |

mm |

|

1000 |

|

|

|

|

|

|

|

|

|

|

|

Feeds 进给 |

|

|

|

|

|

|

|

|

|

Feed range for X, Y and W axes X,Y,W轴进给速度范围 |

mm/min |

|

1-10000 |

|

Feed range for Z axis Z轴进给范围 |

mm/min |

|

1-6000 |

|

|

|

|

|

|

|

|

|

|

|

Main A.C. spindle motor 主轴交流电机功率 |

kW |

|

60 |

|

Total installed power 总装机容量 |

kVA |

|

110 |

|

|

|

|

|

|

|

|

|

|

* Specifications subject to

changes without notification

WOTAN公司保留技术规格变更权力

STANDARD MACHINE FEATURES

机床标准配置特点

The machine electrics are designed and constructed to

meet VDE 0113 standards and are arranged for operation off 440 V. 3 phase 50 Hz

main supply and 115 V. control supply.

The machine electrics are designed and constructed to

meet VDE 0113 standards and are arranged for operation off 440 V. 3 phase 50 Hz

main supply and 115 V. control supply.

机床电器设计和结构符合VDE0113标准,使用440V,3相,50HZ动力电源,控制电源电压为115V。

The main spindle is driven by a totally enclosed, fan cooled variable

frequency controlled AC motor. The

motor meets IP54 protection standards.

主轴驱动电机采用全封闭,风扇冷却,变频控制的交流电机。电机的保护等级为IP54。

All axes are also driven by AC variable frequency controlled servo

motors. These motors and drives

represent the latest servo control technology and provide a very high degree of

reliability with low maintenance costs.

所有进给轴采用变频交流伺服电机驱动。这些电机和伺服驱动系统采用最新的伺服控制技术,可提供极高的可靠性和极低的维护成本。

Position feedback for the 3 linear axes "x", "y" and

"w" is provided through precise

Heidenhain linear scales type LB 382 and LS 186. The

spindle "z" axis positional

data is provided by a built-in encoder coupled to the "z" axis

servo motor.

X,Y和W 三轴的位置反馈通过精密的海登汉线性光栅尺完成,光栅尺型号分别为LB382(X,Y轴)和LS186 (W轴)。镗杆Z轴的位置数据反馈由内置的编码器实现,编码器与Z轴伺服马达连接。

The Cutmax 3 FT-K design incorporates a wide stable, 3 way bed for the

"x" axis. A double

pinion anti-backlash combination with a precision rack provides smooth precise

feeds for accurate contouring in the "x" axis. Additionally the column is mounted on a

cross sliding saddle that provides a "w" axis parallel to the spindle

"z" axis. This 4th axis

is very useful when using accessories such as angular milling or facing heads

and for precise machining of deep cavities in large work pieces.

Cutmax 3FT- K机床的X轴采用了具有很高的稳性的3导轨床身。具有反向齿隙误差补偿的双齿轮啮合一根精密齿条提供X轴平滑精密进给。另外,立柱安装在十字床鞍上可提供平行于Z轴的W轴向运动。当使用附件头(如角铣头,端面铣头)对大工件中的深腔体进行精密加工时,该第四轴非常有用。

Cutmax

3 FT-K machines have aerostatic ways. In this anti-friction guideway system,

clean, dry and filtered air is introduced into a preloaded gap between the

stationary machine members and the slides. Properly selected slideway dimensions, air pressure and

preload create a very stiff, virtually friction free interface. The way surfaces and guides are lined

with Rc 60 hardened and ground steel inserts. Air bearings are open loop and by

creating a pressurized space in the way interface area, are by nature self

cleaning and offer added protection against dust and chip contamination.

Cutmax 3 FT-K机床采用气浮导轨。在该抗摩擦导轨系统中,洁净,干燥和经过过滤的空气被导入到机床静止部件和床鞍间经过预留的间隙中。适当地选取滑轨尺寸,空气压力和预载荷可实现高刚性,无摩擦的滑动。导轨表面和导向面上贴有硬度为

RC 60,经硬化和磨削的钢膜。空气轴承是开环的并可在导轨的接触面上形成一个正压的层,并且具有自清洁功能,可提供保护防止灰尘和切屑进入部件内。

The headstock contains the nitrided precision boring and milling spindle

assembly. The milling sleeve runs

in hydrostatic bearings, which provide very precise circularity and virtually

friction free operation. The

hydrostatic bearings and the headstock gear oil supply is cooled by a

thermostatically controlled refrigeration system. A four (4) speed / stage, hardened and ground gearbox provides a quite high torque transmission for

the 60KW

available from the main AC motor. The

stepless speed range provides the most useful speeds for boring and milling

applications.

主轴箱内装配了经过渗氮处理的精密镗铣轴。铣削套筒旋转采用静压轴承支撑,它可以提供非常精密的圆度和无摩擦的旋转。静压轴承和主轴箱齿轮油通过具有恒温控制的冷却系统冷却。四级经硬化和磨削的齿轮箱可传递从60KW主轴交流电机输出的极高扭矩。在镗铣加工应用时无级变速系统可提供了最合理的转速。

The "y", "z" and "w" axes are moved

through hardened and ground ball screws and double recirculating ball nuts pre-loaded

to eliminate backlash. The

"x" axis is driven through an antibacklash double pinion and rack

transmission.

Y, Z 和W轴是通过硬化和磨削处理的滚珠丝杠驱动,并且双循环球丝母通过预载削减了反向间隙。X轴是通过消隙的双齿轮和单齿条驱动。

The "x" axis is fully protected by telescopic steel way

covers. The "w" axis is

protected by a flexi-steel apron and the "y" axis ball screw is

covered with a way cover.

X轴装有钢制伸缩导轨护罩。W轴装有可弯曲钢制挡板。Y轴滚珠丝杠由导轨护罩保护。

The machine is tested to ISO 3070-1; however, using the tighter original

Wotan Düsseldorf tolerance specifications. These demanding values assure long term precision and

reliability.

机床按照ISO3070-1标准进行测试,使用比德国杜塞尔多夫原WOTAN工厂标准更严格的公差标准制造。这些近乎苛刻的要求是确保机床能长期保持高精度和高可靠性运行不可缺少的。

Standard color is RAL 7038 Agate Gray, and RAL 7012 Gray .

机床标准颜色:玛瑙灰 RAL 7038,灰色RAL 7012。

Other colors are available at extra cost.

其它颜色需要额外付费。

The 4 axis Siemens Sinumerik 840D CNC provides 3D Interpolation

contouring control. Other controls are available at extra cost.

四轴西门子840D数控系统可提供3D插补轮廓控制。若需其它控制功能,需额外费用。

A detailed specification is attached to this offer.

详细的规格已附在此报价中。

Column mounted work light.

立柱上装有工作灯。

Operator's platform

操作者平台

Power draw bar

动力拉杆

THE PROPOSED MACHINE ALSO INCLUDES THE

FOLLOWING:

方案中的机床还包括以下配置:

HEAVY DUTY HEADSTOCK

重载主轴箱

Spindle

diameter 160mm with hydrostatic bearing and replaceable

spindle taper, and spindle speed is

2-2000 rpm.

镗杆直径为160mm,采用静压轴承,可更换的镗套,转速范围2-2000rpm.

CHIP CONVEYOR WITH FLOOD COOLANT

排屑器和喷淋系统

This

system consists of a hinged belt conveyor for the 6 meters of “x” axis travel

with the Flood Coolant Equipment.

对6米X轴行程上的排屑系统由铰接的带式传输机和喷淋冷却系统设备组成。

External 外部冷却

Pump

delivery 150

l/min.

泵流量

Pressure 0.6

bar

压力

Flood coolant is supplied through flexible adjustable

nozzles.

喷淋冷却液通过几个柔性可调的喷头对刀具进行冷却。

TOTAL PRICE OF THE MACHINE WITH ALL

ABOVE LISTED ITEMS

上述所列的配置的总价:

CIF CHINESE PORT …………………………..........……………..………..

CIF 中国港口:

OPTIONAL

FEATURES AND ACCESSORIES

选项和附件

|

2TT-670 |

FLOOR PLATES 15 TON PER SQUARE METER (1500 mm x 3000

mm) 平台每块1500 X

3000mm,承重15吨每平方米 |

Includes

co-axial leveling screws, dust covers, fluid drain gutters and provision for

grouting. The plates are made of

ASTM A48-76 Hi-alloy cast iron with a 160 - 220 Brinell hardness. Includes fixators.

包括共轴水平调整螺栓,防尘盖板,排液沟槽和灌浆材料。平台是由ASTM A48-76 高合金铸铁制成,其硬度为160-220 布氏硬度。还包括地脚垫铁

。

|

|

......................................................................................... |

US$ |

|

AUTOMATIC TOOL CHANGER

刀具自动交换库

Tool

Magazine Chain

Type

刀库型式

链式

Tool

Pockets CAT

50

刀位形式

Tool

Selection Random

刀具选择方式

随机

Max.

Tool Diameter, All Pockets Full 120

mm

所有刀位满时,最大刀具直径

Max.

Tool Diameter, Adjacent Pockets Vacant 360

mm

相邻刀位空时,最大刀具直径

Max.

Tool Length 500

mm

最大刀具长度

Max.

Tool Weight 35

kg

最大刀具重量

Average

Tool Weight, All Pockets Full 20

kg

所有刀位满时,平均刀具重量

Average

Cut-to-cut change time 30

sec.

平均切削到切削的换刀时间

*Oversized

bridge type tools are possible (>360

mm) subject to confirmation

可选用直径大于360 mm超大型盘式刀具

|

2TT-110 |

Chain magazine 40 tool storage 链式刀库40把刀位 |

US$ |

|

|

|

|

|

|

|

2TT-111 |

Chain magazine 60 tool storage

链式刀库60把刀位 |

US$ |

|

|

|

|

|

|

|

2TT-112 |

Chain magazine 80 tool storage

链式刀库80把刀位 |

US$ |

|

|

2TT-800 |

Table 12,5 D (2500 x 2000

mm) rotary tables, 12,5 ton load

capacity 12.5吨承重,2500×2000mm的旋转工作台 |

|

|

|

|

................................................................................................. |

US$ |

|

|

2TT-810 |

Table 25 D (2500 x 2000 mm)

rotary tables, 25 ton load

capacity 25吨承重,2500×2000mm的旋转工作台 |

|

|

|

|

................................................................................................. |

US$ |

|

SIEMENS SINUMERIK 840D CNC

西门子840D数控系统

SINUMERIK 840 D

with latest edition. This CNC can control X, Y, Z, W, B

five axes and any four of five axes can be combined for operation for feeding.

采用西门子840D最新版的数控系统。数控系统能控制X, Y, Z, W,

B并且五轴中任意四轴联动。

1.

Digital control up to 31 axes depends on the chose CPU – 32 bits processor.

32位CPU可使数控系统最高可控制31轴

2.

CNC users memory of 256 Kbytes. Expansible up to

2,5 Mbytes depends on the chose CPU.

256Kb数控高速缓存,根据选用不同的CPU,可达2.5Mb.

3.

Windows

operational system on

PCU50, 2G to 4G byte of free storing memory for

programs and data. At present we offer Windows XP or NT.

基于PCU50,模块的 Windows 操作系统, 可提供2G to 4G程序或数据存储空间。目前,我们可以提供Windows XP 或Windows

NT 操作系统。

4.

NC programming commands with accessibility to load read and write into

machine data (NC, MD), PLC machine data (PLC, MD), setting data, tool

compensation, zero offsets, math functions (+, - , x, ÷ and square root, as well as

trigonometric functions).

数控程序指令可直接进行读写机床数据、PLC机床数据、设置参数、刀具补偿、零点偏移、数学公式(+, - , x, ÷ 和开方根,以及三角函数)。

5.

Linear and

circular interpolation

直线和圆弧插补

6.

Operator

interface under MS Windows with an easy to use interactive programming facility

with a 2D/3D simulation for program check.

基于 Windows NT 的操作界面,操作者可运用交互式编程工具对二维/三维模拟的程序进行核对。

7.

Metric or inch

measuring system

公制或英制测量系统

8.

Chamfer and

radius inclusion, multipoint definition

倒角和半径混合编程,多点定义

9.

Machine cycles

机床功能循环

10.

Drilling and

tapping cycles (G81-G89)

钻削和攻丝循环(G81-G89)

11.

Milling cycles

铣削循环

12.

Rectangular

and circular pockets cycles

直角和圆腔循环

13.

Contouring

cycles

轮廓循环

14.

Measuring

cycles

测量循环

15.

User

programmable cycles

用户编程循环

16.

Tool

compensation

刀具补偿

17.

Tool radius

compensation

刀具半径补偿

18.

Dry Run

federate

空运行

19.

Liquid crystal

monitor TFT 10,4"

液晶显示器TFT 10,4"

20.

Softkey menus

软菜单

21.

NURBS Interpolation, high speed pre-reading

sequence section of more than 128 MB

NURBS插补,高速预读128MB以上程序段。

22.

Failures

diagnostics on the NC and on the

PLC by the interface, with texts on the screen.

数控故障诊断和通过接口实现PLC诊断,并在屏幕上以文本显示

23.

3D

interpolation

三维插补

24. Post treatment of processing

software (UG) for programming and computer aid design, and other software and

hardware, automatically generating cutting processing sequence in the computer

system, realizing auto programming and simulation of cutting.

供编程和计算机辅助设计使用的加工软件(UG)的后置处理器和其它应该配备的软硬件,能在计算机系统内自动生成切削加工程序,实现自动编程,可在计算机上实现切削加工仿真。

25.

Man-machine interaction programming and cutting

data expert system

人机交互式编程和切削数据专家系统

26.

Integrated PLC

内置式

27.

Electronic

handwheel

电子手轮

28.

Graphic

simulation

图形模拟

29.

Program

editing simultaneous with the machining

加工同时编程

30.

Mill and drill

configuration by polar coordinates and sub routines.

通过极坐标和子程序实现铣削和钻削功能

31.

Rigid tapping

and feed / resolution

刚性攻丝和进给/旋转

32.

Spindle

orientation (M19)

主轴定向(M19)

33.

Functions M and

T

M和T功能

34.

Helical

interpolation

螺旋插补

35.

Re-start of

the program

程序重起

36.

RS 232 data

transfer communication

RS 232数据传输通信接口

37.

Digital system

drives integrated SIMODRIVE 611 D

SIMODRIVE 611D集成式数字驱动系统

38.

Floppy drive

to 3 ¼” floppy disks

3 ¼”软驱

39.

Up to 2

measuring in process probes connecting possibilities

可连接两个测头

40.

Self-diagnostic and alarm function (incl. cutter

breakage, life management, overload supervising, shift of spare cutter, auto

measurement, original point compensation)

完整自诊断及报警功能(含刀具破损、寿命管理,过载监视、备用刀变换、自动测量、原点补偿)。

GENERAL CONDITIONS

通用条款

DELIVERY

交货期

The offered

basic machine can be delivered within 10-12 months, ex-works,

subject to prior sales, after receipt of firm order and down payment. Delays caused by changes in the

purchase order and any costs caused by such delays will be charged

additionally.

在收到定单和定金后10-12个月内机床可发货出厂。由于定单变更和付费延迟所造成的机床交货延误,将收取额外费用。

PRICE BASIS

价格基础

The prices

quoted are valid as of June 1st, 2004 and are CIF port of

entry. Inland transport, unloading

of the machine and rigging costs onto your site are for your account and risk.

报价于2004年6月1日生效,为CIF中国入境口岸(港口)价格。在用户处的内陆运输,卸货和绑扎费用为用户承担,各种风险也由用户承担。

Any local

taxes such as sales taxes, etc., are not included in our prices and will be

charged separately if required.

任何当地税费没有包括在报价中,如果需要可以增加到报价中。

The prices

quoted are firm for 30 days from the date of this quotation.

报价有效期为30天。

PAYMENT TERMS

付款条款

According to

Agreement.

可根据双方协议

WARRANTY

保修

The warranty

of machine, numerical control and accessories is valid during a period of 12

(twelve) months with one working-shift, commencing as of the final acceptance

test at your plant.

一班制的情况下机床、数控系统和附件的保修期为机床最终验收后的12个月

This warranty

does not include components subject to wear, such as: relays, sensors,

batteries, electric fuses, lamps, belts, roller bearings and alike.

保修不包括任何易磨损部件,如继电器、传感器、电池、保险、灯泡、皮带、滚柱轴承等。

Note: The above warranty is only

valid under the following conditions:

注意:以上描述的保修在以下条件下适用

-

Variations of

voltage (oscillation) must not exceed ± 5% (without peak power). If this

condition cannot be guaranteed, installation of a voltage stabilizer will be

necessary.

电压的波动不超过± 5%(不超过峰值电压)。如果不能保证该条件,需安装稳压电源。

-

Voltage drop

not exceeding a duration of 20 millisecond.

电压下降时间不超过20毫秒

-

Environmental

conditions should be normal (without excess humidity and without ambient

corrosive or other similar conditions, etc.)

环境温度正常(不能过湿和不能在腐蚀环境下或相似状况)

-

Max.

temperature 45°C.

最大温度45°C。

PRE-ACCEPTANCE AT OUR FACTORY

在WOTAN公司预验收

Should you

wish to witness acceptance tests in our works please advise us of this at least

6 weeks before the quoted delivery.

在发货前6周通知我们需要进行预验收

MACHINE INSTALLATION

机床安装

After you have

unloaded the machine, brought it to its intended operating location, unpacked

and cleaned it, please advise us so we can dispatch our field engineer. We will provide you with certified

foundation plans within 60 days after receipt of your order or sooner in the

case of stock machines.

当用户卸下机床,并将机床运到待装机位置,拆箱并清洁后,请通知我们,以便我们派出安装工程师。我们将在收到定单后60天内提供地基图纸,如果我们有存货机床将会更快。

Our field

service engineer will supervise the erection of the machine with help from your

plant personnel (cranes, forklifts, etc.). He will check all geometric alignments and operational

features so that the machine can be accepted and placed in operation.

我们的现场服务工程师将会监督机床部件的吊装,吊装需由用户帮助(吊车、插车等)服务工程师将会检查所有的几何精度和机床功能,以便机床能顺利投产。

The days

required for this work are included in the price of the machine. Should you request additional service

this should be specified in the purchase order and will be billed

separately.

安装工作所需的费用已经包括在机床总价中了,如果用户需要额外的服务需单独付费。

N.B. The machine connection to the main

electricity supply must only be carried out in the presence of our service

engineer.

注意:将机床连接到主电源必须在我们服务工程师在场的情况下进行。

TRAINING

培训

a)

Machine Operator.

机床操作培训

We have included in

our price 3 days of operator training on site.

我们已经包括在现场3天的操作培训

b)

Maintenance.

维护培训

Our service engineer

will instruct your plant service personnel regarding preventive maintenance

during installation of the machine.

我们的服务工程师将会在机床安装期间指导用户的维修人员进行预防性维护培训。

c)

Application

应用培训

An applications

engineer will provide 5 days of programming and operator training for the CNC

control

应用工程师将提供数控系统5天的编程和操作培训。

WOTAN MÁQUINAS LTDA